Menu

717-486-7530

M–F: 8AM–4:30PM

M–F: 8AM–4:30PM

More commonly called rubber roofing, EPDM (Ethylene Propylene Diene Terpolymer) is a popular choice for commercial roofs in central Pennsylvania. It is also classified as a single-ply roof because it consists of one layer of membrane that is installed over insulation as the final waterproofing layer on a single-ply roofing system.

EPDM has been in use on roofs in the U.S. since the 1960s and is one of the most common types of low-slope roofing materials. It’s relatively inexpensive, simple to install, and fairly clean to work with when compared to conventional built-up roofs that are installed using layers of asphalt, felt and hot tar. There aren’t the odors and fumes that accompany built-up roofs which appeals to many property owners and managers.

Building owners can expect a properly installed EPDM roof to last up to 25-30 years. Most manufacturers offer warranties on the roofs as well.

EPDM has performed well on roofs for the last 50 years. It resists fatigue, hail, ozone, weathering, thermal shock, ultraviolet radiation and it maintains flexibility even in extremely low temperatures. Unlike other single-ply roofing systems EPDM will not become brittle or crack. As a thermoset membrane, EPDM recaptures its shape after stretching, helping it perform for decades.

It’s known for it’s high resistance to wind uplift as well and can be designed to meet several Factory Mutual wind uplift standards.

EPDM can be installed using one of three installation methods: fully adhered, mechanically fastened or ballasted. A fully adhered system uses water-based or solvent-based adhesives to adhere the rubber to the substrate. Mechanically fastened EPDM is attached by manufacturer-approved mechanical means to the substrate, and ballasted or loose-laid membranes are secured only at the perimeters and any penetrations, then a ballast of round river rock or concrete pavers is used to hold the materials in place.

EPDM roofs offer one of the best values for building owners. The EPDM Roofing Association cites ballasted EPDM as having the lowest installed cost per square foot, followed by mechanically attached and full adhered systems.

EPDM is also a roofing system that can be easily repaired and restored. Because of its resistance to UV degradation, it maintains its flexibility and integrity. It can often be restored by cleaning the membrane, prepping the surface and applying a coating or other repair material.

Non-reinforced EPDM membranes come in standard thicknesses of 45, 60 and 90 mils. The thicker the membrane, the more it can stand up to foot traffic, hail and resist punctures.

Most non-reinforced membranes can be installed using a fully adhered application or ballasted system. They are available with manufacturers’ warranties in most cases up to 20 years.

Reinforced EPDM membrane is also available in 45, 60 and 90 mils. While not thicker than nonreinforced, the membrane is reinforced from the inside during the manufacturing process. This makes is up to 60 percent more puncture resistant.

Reinforced membrane can be installed using a mechanically attached method and also features manufacturers’ warrantied that can be for up to 20 years.

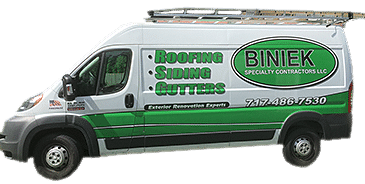

When you choose Biniek for your roofing needs, you can rest assured that the installation of your roof will be the highest quality. Our crews have been certified and trained by the manufacturers of the products that are being installed on your home. We treat every installation as if we were working on our own home.

Prior to your roofing project, you’ll meet with our owner, Paul Biniek, who will review the process and personally address any concerns you may have regarding the installation of your new roof. Our company is fully insured and licensed, carrying $2 million in liability insurance to ensure your protection.

When the installation is complete, you’ll receive all documentation and paperwork for the warranty protection that comes with your new roof.

The EPDM Roofing Manufacturer’s Association states that EPDM is “the number one roofing choice of architects, roof consultants and contractors for both new construction and replacement roofing projects according to market surveys from Building Design and Construction, and Roofing/Siding/Insulation magazines, and the National Roofing Contractors Association (NRCA).”

EPDM’s longevity makes it an ideal choice for building owners who want an environmentally friendly roofing option. Less frequent replacement of the roofing system and it’s ability to be restored keeps waste out of landfills.

The manufacture of EPDM has a low embodied energy number, meaning it uses a lower amount of energy during production.

While EPDM’s formulation has remained pretty standard since its introduction to the market, manufacturers have focused on innovations that provide a higher quality installation and ensure system integrity.

For example, the development of seam tapes have greatly enhanced the integrity of the seams and the introduction of low-odor, low-VOC adhesives results in less disruption to building occupants during installation.

EPDM roofing systems have been known to outlive their warranty periods, leading manufacturers to offer the option for building owners to extend the warranty.

With a roofing system inspection along with the performance of maintenance and repairs, many EPDM roofs are eligible for longer warranty periods, giving building owners peace of mind.

We take pride in our workmanship and invite you to enjoy some of the beautiful rubber roofs that we have installed for central Pennsylvania homeowners.

PA License 034632

GAFME 24043